Date:2022-12-10 Categories:Technical support Download:0 Hits:499

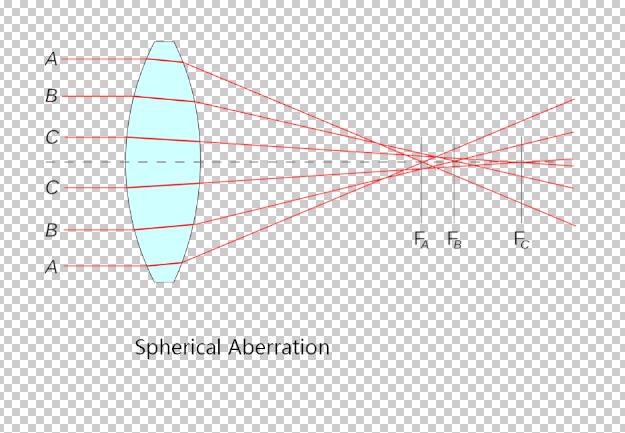

Spherical Aberration:

In spherical aberration(shown in the drawing below), rays of light from a point on the optical axis of a lens having spherical surfaces do not all meet at the same image point. Rays passing through the lens close to its centre are focused farther away than rays passing through a circular zone near its rim. For every cone of rays from an axial object point meeting the lens, there is a cone of rays that converges to form an image point, the cone being different in length according to the diameter of the circular zone. Wherever a plane at right angles to the optical axis is made to intersect a cone, the rays will form a circular cross section. The area of the cross section varies with distance along the optical axis, the smallest size known as the circle of least confusion.The image of spherical aberration is found at this distance.

Correction:

In lens systems, aberrations can be minimized using combinations of convex and concave lenses, or by using aspheric lenses or aplanatic lenses.

An aspheric lens or asphere (often labeled ASPH on eye pieces) is a lens whose surface profiles are not portions of a sphere or cylinder. In photography, a lens assembly that includes an aspheric element is often called an aspherical lens.

The asphere's more complex surface profile can reduce or eliminate spherical aberration and also reduce other optical aberrations such as astigmatism, compared to a simple lens. A single aspheric lens can often replace a much more complex multi-lens system. The resulting device is smaller and lighter, and sometimes cheaper than the multi-lens design.[1] Aspheric elements are used in the design of multi-element wide-angle and fast normal lenses to reduce aberrations. They are also used in combination with reflective elements (catadioptric systems) such as the aspherical Schmidt corrector plate used in the Schmidt cameras and the Schmidt–Cassegrain telescopes. Small molded aspheres are often used for collimating diode lasers.

Manufacture of aspheric lens:

Small glass or plastic aspheric lenses can be made by molding, which allows cheap mass production. Due to their low cost and good performance, molded aspheres are commonly used in inexpensive consumer cameras, camera phones, and CD players.They are also commonly used for laser diode collimation, and for coupling light into and out of optical fibers.

Larger aspheres are made by grinding and polishing. Lenses produced by these techniques are used in telescopes, projection TVs, missile guidance systems, and scientific research instruments. They can be made by point-contact contouring to roughly the right form which is then polished to its final shape. In other designs, such as the Schmidt systems, the aspheric corrector plate can be made by using a vacuum to distort an optically parallel plate into a curve which is then polished "flat" on one side. Aspheric surfaces can also be made by polishing with a small tool with a compliant surface that conforms to the optic, although precise control of the surface form and quality is difficult, and the results may change as the tool wears.

Single-point diamond turning is an alternate process, in which a computer-controlled lathe uses a diamond tip to directly cut the desired profile into a piece of glass or another optical material. Diamond turning is slow and has limitations in the materials on which it can be used, and the surface accuracy and smoothness that can be achieved. It is particularly useful for infrared optics.

Several "finishing" methods can be used to improve the precision and surface quality of the polished surface. These include ion-beam finishing, abrasive water jets, and magnetorheological finishing, in which a magnetically guided fluid jet is used to remove material from the surface.

And our company applies the computer-controlled lathe to manufacture aspheric lenses . With the help of our experienced engineers , our SOP

has been improved as well as our production efficiency. More questions , please contact us.

Previous:No data

Next:No data